Fibre Glast offers adhesives for a variety of applications, from structural bonding paste and marine-grade fairing adhesives to general purpose and infusion spray adhesives. Strength, pliability, viscosity, and cure time vary among the selection and should be considered before starting your composite project or repair.

- Bond and assemble subcomponents to form rigid final structures.

- Strengthen loose fitting joints and panels.

- Generally, repair and bond composites, SMC, foam, wood, many metals, and other common construction materials.

- Create durable, moisture-resistant surfaces for boats and other watercraft.

- Securely position materials within a vacuum bagging layup.

- Bond a wide range of substrates to include decorative laminates and veneers, fiberglass, glass, upholstery, fabrics, foam, boat headliners, cork and particle board.

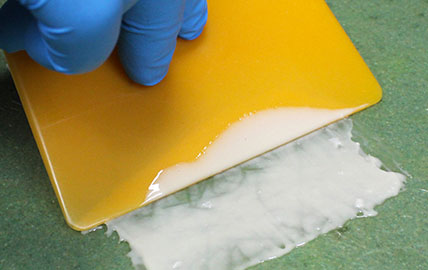

Click on an image below to get more information and pricing on each of our adhesives.

-

These Methyl Methacrylate Adhesives are designed for bonding metals, composites, and other plastic parts. They are...

-

BP20 is a solvent-free epoxy-based bonding paste which was especially developed for fast setting bondings in wind...

-

BP10 is a solvent-free epoxy-based bonding paste which was especially developed for fast setting bondings in...

-

Our #1101 Epoxy Paste Bonding Adhesive is a high strength structural adhesive used to bond and assemble...

-

1601-A Infusion Adhesive is an adhesive specifically designed for the infusion molding process. 1601-A is designed to...

-

1602-A LVOC Infusion Adhesive is a specialty industrial spray adhesive specifically designed for the infusion molding...

-

1603-A General Purpose Adhesive is a high performance and versatile industrial strength contact adhesive. Water...

-

1604-A Marine Adhesive is a high performance industrial strength contact adhesive formulated with zero VOCs to comply...

When bonding composite materials, it is important to use adhesives that are specifically designed for this purpose. The choice of adhesive depends on several factors, including the type of composite material, the intended application, and the required performance characteristics. Here are two commonly used adhesives for bonding composite materials:

- Epoxy Adhesives: Epoxy adhesives are widely used for bonding composite materials due to their excellent strength, durability, and resistance to chemicals and temperature variations. They provide high bond strength and are compatible with various composite reinforcements, including fiberglass, carbon fiber, and aramid fibers. Epoxy adhesives also offer good gap-filling capabilities and can be tailored for specific cure times and viscosities.

- Methyl Methacrylate Adhesives (MMA): MMA adhesives, also known as structural adhesives, provide excellent bonding strength and toughness. They offer good adhesion to a wide range of substrates, including composite materials, and have high resistance to impact, peel, and shear forces. MMA adhesives are commonly used in structural applications, such as bonding composite panels and components.

- Spray Adhesives: We carry a line of spray adhesives that are specifically formulated for use with composites including Infusion, Low VOC Infusion, Marine and General Purpose. These products will not interfere with the polymer matrix integrity and will cross-link with resins to create an integrated matrix.

It is essential to follow the guidelines and recommendations when selecting and applying adhesives for bonding composite materials. Proper surface preparation, including cleaning and roughening the bonding surfaces, is crucial to ensure optimal adhesion. Additionally, considering the specific requirements of the application, such as load-bearing capacity, flexibility, and environmental conditions, will help in choosing the most suitable adhesive.

You can place an order right here on our website or, if you have any questions, call 1.800.838.8984 | 8 a.m. - 5 p.m. EST Mon-Fri.