Collection: Chopper Gun & Roving

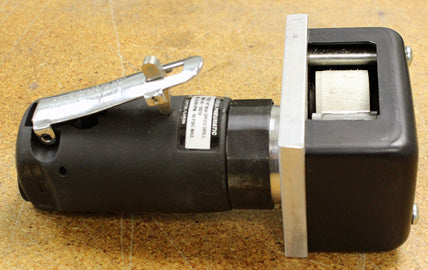

A Chopper Gun is used to automatically chop and deposit fiberglass gun roving strands or carbon tow strands into a mold or composite part. The Chopper Gun makes it easy to quickly cover large surfaces with fiberglass. Fiberglass Gun Roving is fed through the back of the gun in a long continuous piece. An adjustable blade assembly controls the size of the fiberglass strands, and the trigger controls the speed at which these strands are ejected from the gun and onto the mold surface.

Click on an image below to see more information and view pricing.

Products

-

Shop Now1 review

Extend the Life of your Chopper Gun

5.0 / 5.0

(1) 1 total reviews

-

-

Discover chopper guns, fiberglass roving, and essential parts for efficient composite manufacturing. Our tools and materials help you quickly chop and deposit fiberglass or carbon tow to cover large surfaces with ease.