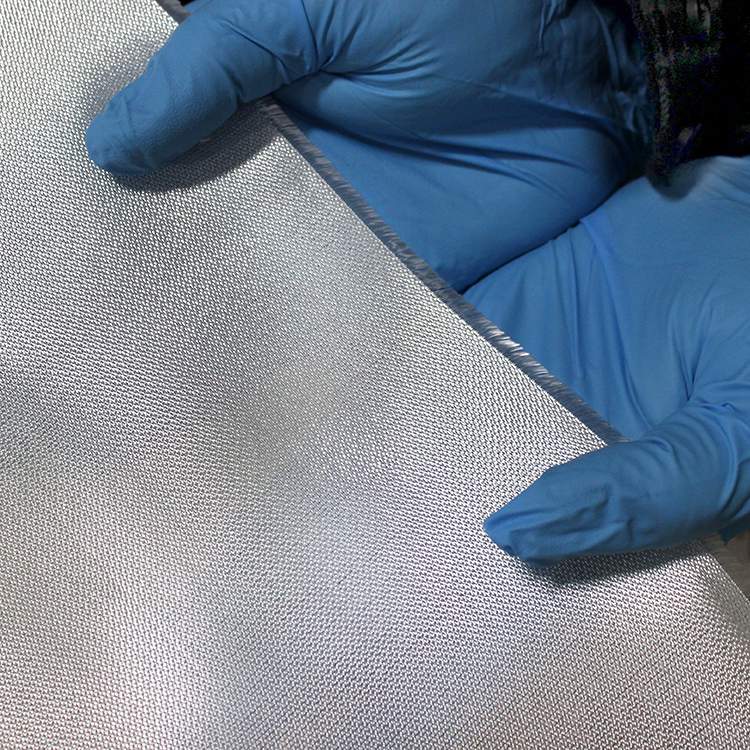

Style 120 E-Glass

Details

Details

Extremely Lightweight for Aerospace Parts

Satin weave fabrics are frequently specified for aerospace and structural applications, and offer excellent strength and surfacing characteristics.

The 4H Satin Weave, in particular, is very lightweight and tightly woven, with fiberglass bundles repeatedly woven to float over three bundles, then under one.

Features

- Satin weaves are flatter than other weaves and conform to shapes easily.

- Provides greater strength over standard plain weave fabrics, making it ideal for aerospace applications.

- If requested, this fabric can be certified to meet the requirements of: AMS-C-9084 Type III (Class 1 and 2), AMS-3824 Style 120 and ASTM D 4039-09 Style 120.

Tips

- Although they conform well to shapes, satin weaves can be more easily distorted than other weaves.

- Each side of this fabric is either largely fill or warp fibers, so opposite sides will look much different. To produce a symmetrical laminate, invert half the plies.

- Use with epoxy resin, polyester resin, or vinyl ester resin to produce composite parts of excellent strength, low weight, and great cosmetics.

- To maximize strength in parts, use with an epoxy, like our System #2000.

Specifications

| Style | 120 |

| Warp | 58-62 |

| Fill | 56-60 |

| Strength (Warp) | >85 lbs/inch |

| Strength (Fill) | >75 lbs/inch |

| Weave | 4H Satin Weave |

| Full Roll | 125 yards (typical) |

| Thickness | 0.003" - 0.006" |

| Color | White |

| Weight | 2.8 - 3.3 oz/yard² |

Guarantee

Fibre Glast is committed to ensuring that every roll of fabric we handle is First Quality and manufactured to the highest standards, so that you can expect the same properties and handling characteristics every time you order.

Click here for more information on our First Quality Guarantee.

Data Sheets

Data Sheets

Shipping

Shipping

Sizes

Sizes

Collapsible content

Videos

Reviews

A nice combination of light weight and strong. Watch out if You use tape to cut this, it will not stay together when tape is removed. Pace tape to the outside of Your cut. Otherwise it is great. Arrived well packed and ready for work.

Your online ordering website is very user friendly. Placing an order is quick and easy. The order was shipped the same day it was placed. Great Customer Service!!!