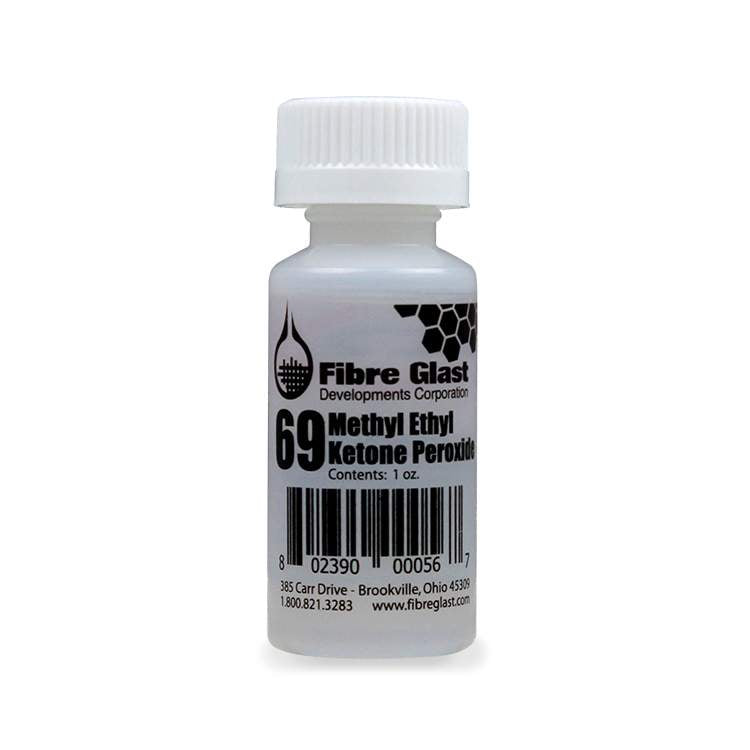

MEKP Hardener

Details

Details

Industry Standard Catalyst

MEKP (Methyl Ethyl Ketone Peroxide) is a catalyst used in the composites industry for polyester and vinyl ester resins and gel coats. It reacts with resin to turn it from a liquid to a solid (cure it). It is used in varying ratios, generally between 1%-3%, depending on the product being used.

Each resin product is available as a kit with enough MEKP to catalyze. However, MEKP may be purchased individually, as shown here.

MEKP is an organic peroxide and should always be handled with care, using the appropriate Personal Protective Equipment.

MEKP (Methyl Ethyl Ketone Peroxide) is a commonly used catalyst in composite manufacturing processes. Here is some information about the use of MEKP as a catalyst in composites:

- Role of Catalyst: In composites, a catalyst is used to initiate and accelerate the curing or hardening of the resin system. MEKP is a free radical initiator that triggers the polymerization reaction in polyester and vinyl ester resins, leading to the formation of a solid and durable composite material.

- Mixing with Resin: MEKP is typically mixed with the resin system just before application. The ratio of MEKP to resin is carefully controlled to achieve the desired curing characteristics and processing time. The specific ratio and mixing instructions may vary depending on the resin manufacturer's recommendations.

- Curing Process: Once MEKP is mixed with the resin, a chemical reaction starts that causes the resin to crosslink and solidify. The curing process can be accelerated by applying heat, which helps to speed up the reaction and shorten the overall curing time.

- Safety Precautions: MEKP is a hazardous substance and should be handled with caution. It is flammable and can release toxic fumes, so appropriate safety measures, such as wearing protective gloves, goggles, and working in a well-ventilated area, should be followed. Always consult the safety data sheet (SDS) and follow the guidelines for proper handling, storage, and disposal.

- Shelf Life: MEKP has a limited shelf life and can degrade over time, affecting its effectiveness as a catalyst. It is important to check the expiration date and use fresh MEKP to ensure reliable curing performance.

It is important to note that the specific curing characteristics and processing parameters can vary based on the type of resin, ambient conditions, and specific composite application. Always refer to the guidelines and follow the recommended curing instructions for the best results.

Data Sheets

Data Sheets

Shipping

Shipping

Sizes

Sizes

Collapsible content

Reviews

enjoyed working with this product. did a great job

Ordered gel coat , first order , had quick shipping second order still quick shipping but one can of duralast was damaged do to poor packaging bubble wrap was stuffed Ian top of the cans none on the bottom or sides attention to detail or Quality control can make or break a company ,good products , please improve on packaging give you a 5 star it could change if I get anymore damaged products like I got today

MEK is MEK it does what it should.The small bottles though are difficult to work with and would be great if had a dropper top or something of that nature built in to dispense else when trying to just get a few drops it runs down the side of the bottle.My solution was a 1ml medical syringe with the needle cut off. A dropper nozzle cap would have solved this more conveniently.

I have used this product before and was very pleasedwith the results. So naturally I went back to the sameproduct and was again pleased with the results.

Quality stuff.