Duratec® Clear Hi-Gloss Gel Coat Additive

Details

Details

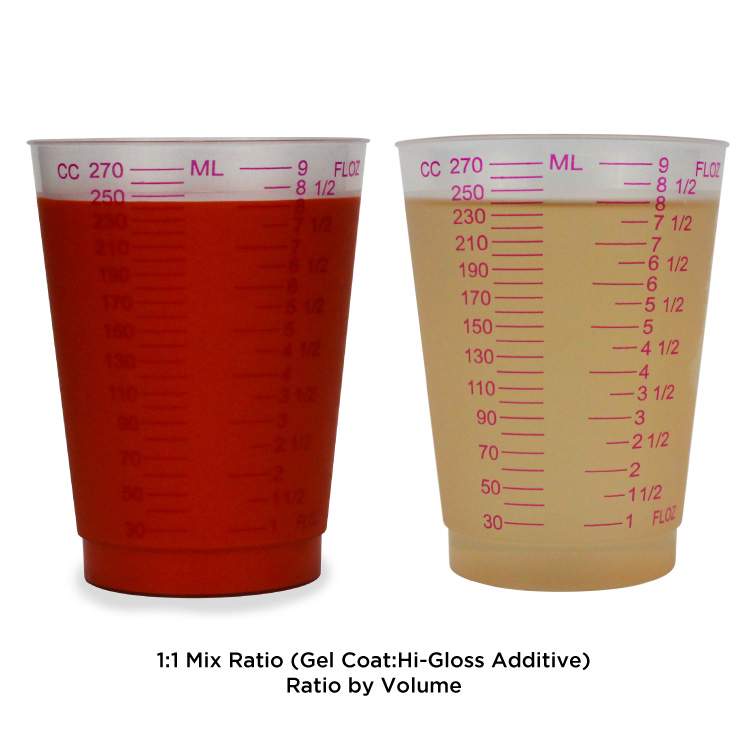

Duratec® Clear High Gloss Additive can be blended with numerous gel coats to create a glossy, smooth finished surface. Mix at a 1:1 ratio with regular gel coat to reduce viscosity and porosity, improve gloss level, and permit a complete open-air cure. It can also be blended at 15% with tooling gel coats to upgrade mold surfaces, improve gloss retention, increase impact resistance, and reduce heat distortion.

The reduction in viscosity allows gel coats to be sprayed controllably through siphon and HVLP equipment, reducing sanding and polishing time. When used for repairs, this product will result in a low porosity surface.

PLEASE NOTE: When making below-the-waterline repairs on boats, we recommend adding our #71 Styrene Wax to maximize hardness.

Requires 2% MEKP.

Duratec® is a registered trademark of DURA TECHNOLOGIES INC.

Data Sheets

Data Sheets

Shipping

Shipping

Sizes

Sizes

WARNING: This product can expose you to chemicals including Styrene, which is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov

WARNING: This product can expose you to chemicals including Styrene, which is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov

Collapsible content

Videos

Reviews

Works great

Great stuff would recommend to anyone

Pros, As advertised the gloss enhancement is outstanding the finish piece has the reflectivity of still water. When added to gelcoat it does let the mixture cure while exsposed to air. One unantisipated result however is that the product when used in a 50% mix with the gelcoat is that it dilutes the color of a premixed gelcoat making the color lighter after curing. So if your like I am an not a color nixing guy you may want to start with a shade or 2 darker gelcoat on the fan deck. Another effect of the thinning of the gelcoat is that the color if light in shade will not cover the substrate if it is dark in color. To help with this aspect I used white pigment in the resin mixtures in the layup, and it helped considerably. Otherwise it mixes well with the gelcoat and pours like 40 wieght oil out of the can, even has the same shade. Dave IrwinEast Boston MA

Great transaction ,great product !

Josh helped me a lot... Good guy . Really knows what he's talking about..